The Synchronizer System is a collection of precision-engineered set of metal rings that work in tandem within a manual transmission to provide highly smooth engagement of gears as they are shifted. As the name suggests, these rings synchronize the parts that are spinning at different speeds within the transmission system.

We supply multi-cone steel-based synchronizer systems with carbon lining (single, dual & triple cone) to several leading Indian customers. Recognizing the inherent advantages of steel as a metal for synchronizer rings over brass, Divgi-TTS pioneered the introduction of steel based synchronizer systems in India and currently is the biggest Indian steel synchronizer systems supplier.

Single Cone

Dual Cone

Triple Cone

Key Features

Multi-cone Connected Systems

- High levels of torque

- Reduced gear shift time

- Reduced hand ball / actuation loads

- Performance advantages in terms of shift quality and refinement

High Mechanical Strength

- Heat-treated steel for outer synchronizer rings

- High shift force accommodation capacity

- Smaller tooth module

- Patented ‘Bent Lug’ design

Composite Friction Materials

- Improved frictional characteristics

- Constant friction levels

- No wear of friction materials

Reference Gauge Diameter

- 47 mm

- 60 mm

- 74 mm

- 76 mm

- 78 mm

- 86 mm

- 90 mm

- 114 mm

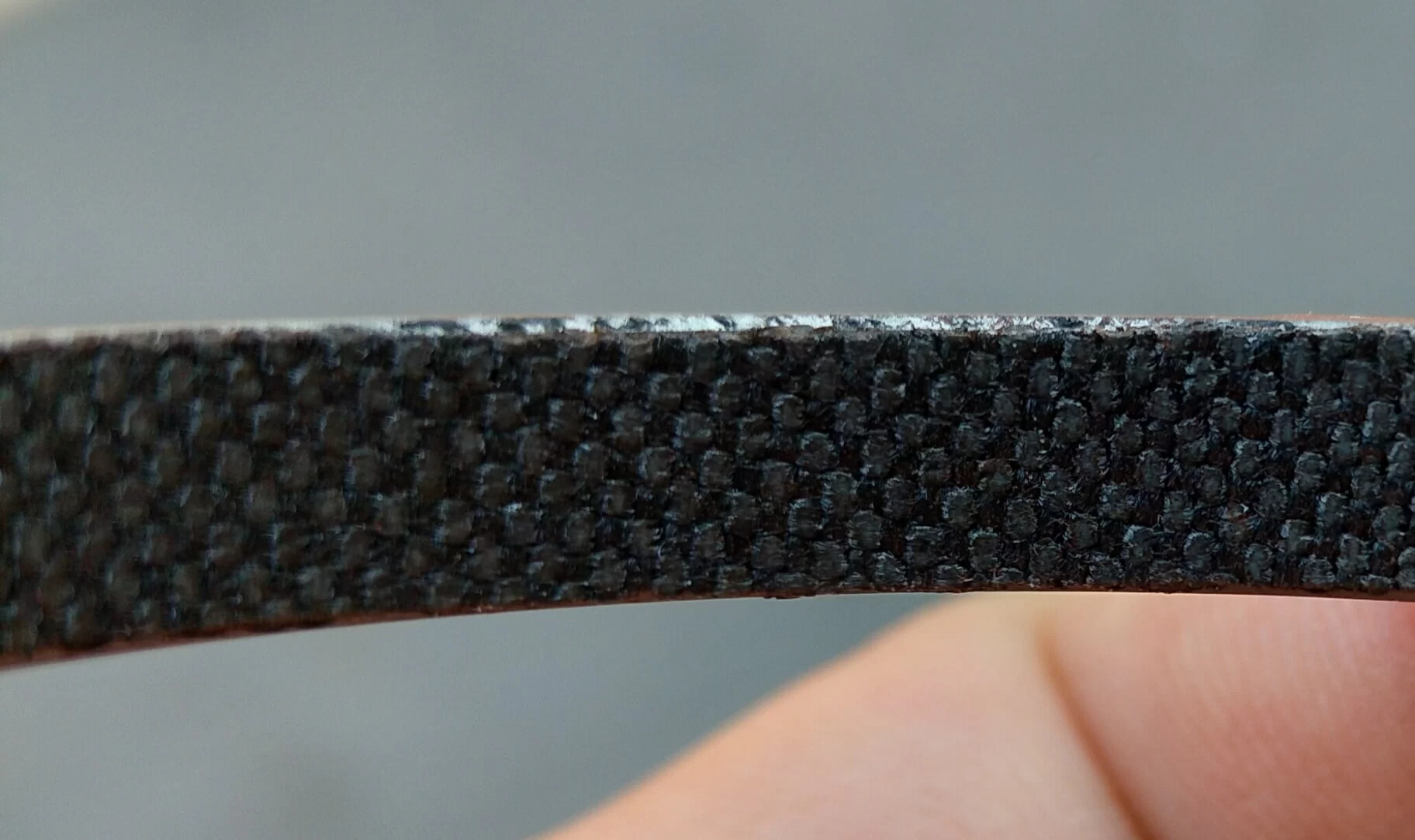

Carbon Friction Material Technology

Carbon Composite

- High dynamic coefficient

- High reliability

- Low shift effort

- Passenger car application

Woven Carbon

- High energy absorption

- High durability

- Withstand abuse

- Heavy duty application